-

Home > News & Events > Blog > Enzymes

Heparin sodium, known as the "golden drug" for clinical anticoagulant therapy, is widely used in cardiac surgery, hemodialysis, and the prevention and treatment of thrombosis. The traditional extraction process relies on chemical methods using strong acids and alkalis, which is plagued by problems such as low purity, significant activity loss, and severe pollution. Meanwhile, the currently widely used salting-out extraction method also has limitations, including low product potency.

The adoption of the combined enzymatic hydrolysis-salting-out extraction method can significantly improve the potency and yield of the product while reducing environmental pollution.

Principles Related to the Combined Enzymatic Hydrolysis & Salting-Out Extraction Method

In a natural state, heparin and proteins are tightly bound through ionic bonds to form stable complexes. The salting-out technology disrupts the hydration layer on the protein surface, causing the proteins to denature and precipitate. Meanwhile, the enzymatic hydrolysis technology is integrated to hydrolyze large protein molecules into small peptides and free amino acids. This process fully releases the heparin bound to proteins. Subsequently, heparin with a large number of negative charges combines with positively charged sodium ions, completing the preliminary extraction of heparin sodium.

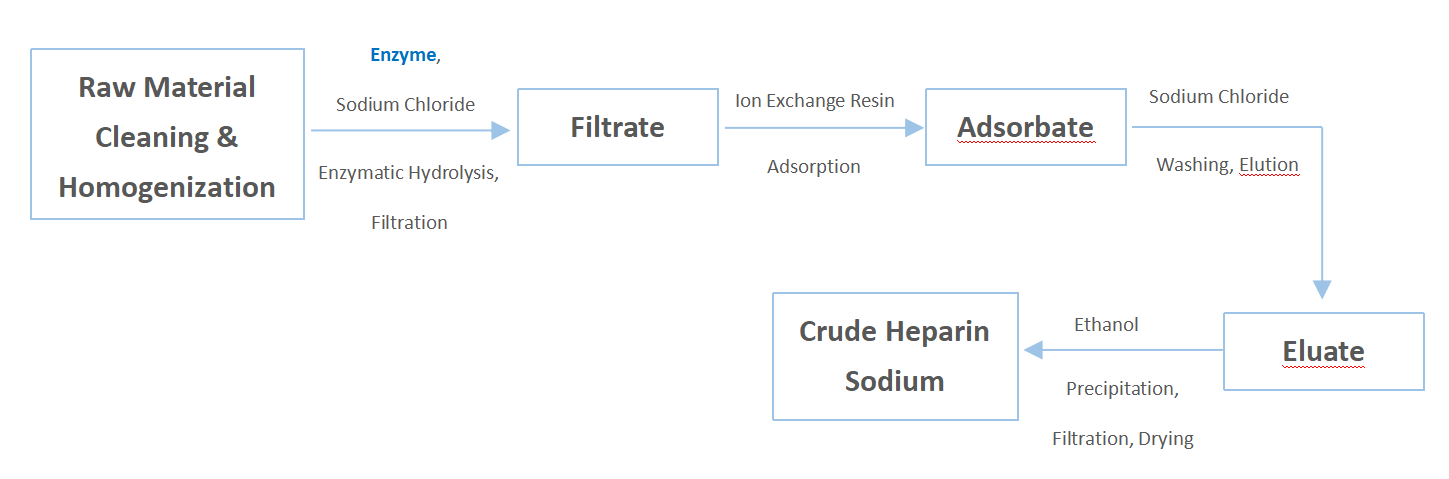

Related Processes of the Combined Enzymatic Hydrolysis & Salting-Out Extraction Method

Control of Key Process Parameters

(1) Enzymatic hydrolysis process: enzyme addition amount, sodium chloride concentration, solid-liquid ratio, temperature, pH, time;

(2) Adsorption process: resin selection, resin addition amount, temperature, pH, time;

(3) Elution process: sodium chloride concentration, elution times, elution time;

(4) Precipitation process: ethanol concentration, precipitation time.

Advantages Related to the Combined Enzymatic Hydrolysis-Salting-Out Extraction Method

(1) Reduce chemical residues and improve product yield and purity;

(2) The extraction conditions are relatively mild, which reduces activity loss and improves product potency;

(3) The enzymatic hydrolysis filtrate, which contains a relatively high content of small peptides, can be processed into high-quality feed-grade protein powder, promoting resource recycling and reducing environmental pollution;

(4) The increase in product potency, recycling of protein resources, and reduction of pollutants in discharged wastewater enhance the economic benefits of production.

The combined enzymatic hydrolysis-salting-out process achieves dual-effect synergy, realizing a three-in-one breakthrough in the efficient extraction of heparin sodium, recycling of protein resources, and green and controllable production emissions!

About Annzyme®:

Annzyme is a new brand for Angel enzymes products. We are dedicated to providing customers with perfect solutions in many fields like baking, proteolysis, nucleic acid hydrolysis, starch further-processing etc, and already built highly automated production lines for enzymes and other biological products. We are committed to become the best enzymes supplier and service provider.

Press contact:

Angel Yeast Co., Ltd.

Address: 168 Chengdong Avenue, Yichang, Hubei, P. R. China

Tel: +86-717-6369520

Fax: +86-717-6370680

Email: lili@angelyeast.com